Stepper Motor or Servo Motor: Which One Should You Use?

Share

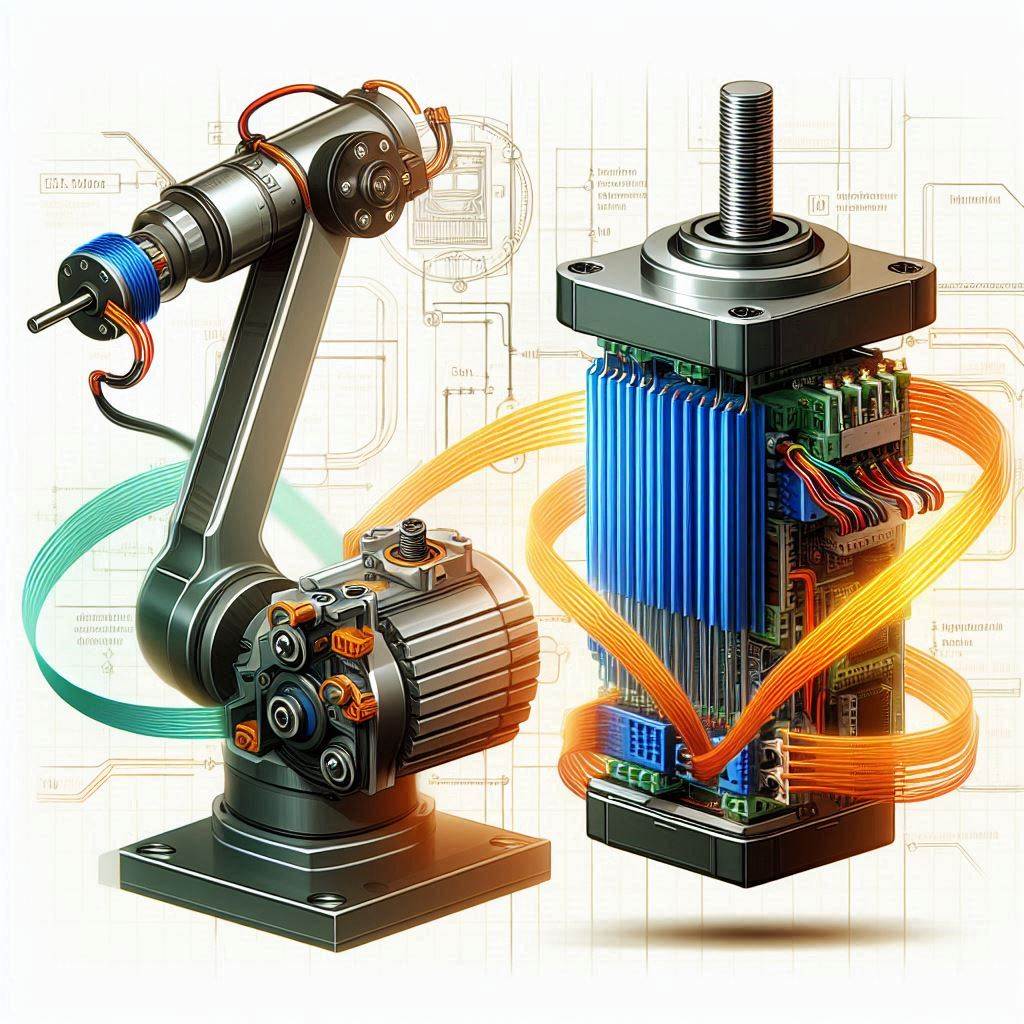

So, you're working on a project that involves moving something—maybe a robot arm, a camera slider, or even a 3D printer. You’ve narrowed it down to two options for motion control: stepper motors and servo motors. But now you’re stuck. Which one is better? Which one will take your project to the next level and which one might leave you yelling at a tangle of wires?

Let’s dive into the nerdy but super useful world of stepper motors and servo motors. By the end of this, you’ll not only know which motor to use, but you'll probably feel like you just leveled up in your engineering or DIY skills.

What is a Stepper Motor?

Imagine trying to turn a knob one tiny step at a time, where each click is precise and predictable. That’s basically what a stepper motor does, but a lot faster and without you twisting anything. Stepper motors rotate in discrete steps, meaning the motor moves a set amount every time it's given a command.

Here's why that's awesome:

-

Precision: Stepper motors are all about control. They move in fixed increments (or steps), making them great for projects where you need high accuracy, like 3D printers, CNC machines, and robot arms.

-

No Feedback Required: A stepper motor doesn’t need feedback to know where it is (fancy term: “open-loop system”). You tell it to move 100 steps, and it’ll do exactly that. No guesswork involved. Think of it like a robot that follows orders exactly but never checks to see if it’s made a mistake (spoiler: it rarely does).

-

Hold Position: Once a stepper motor moves to a certain position, it can hold that position without any extra sensors or fancy electronics. This is perfect for applications where you need something to stay still, like holding a camera in a certain direction.

Use Cases for Stepper Motors:

- 3D Printers: Stepper motors make sure the printer head moves exactly where it should—down to a fraction of a millimeter.

- CNC Machines: You can carve intricate designs with the precision of a stepper motor.

- Robotics: They’re great for things like robotic arms, where precise movement is key.

Drawbacks? Stepper motors aren’t the best when it comes to speed or torque. They also tend to get a bit "shaky" at high speeds and can lose steps if you push them too hard (kind of like you after a long day of cramming for finals).

What is a Servo Motor?

Now, let’s talk about the servo motor, which is basically the James Bond of motors—smooth, efficient, and always on target.

Unlike stepper motors, servo motors don’t move in steps. Instead, they use continuous rotation and rely on a feedback loop to tell them exactly where they are. This makes them extremely precise and reliable, especially when you need smooth, controlled motion.

Here’s the kicker:

-

Feedback Loop: Servo motors have built-in sensors (typically encoders) that constantly check their position. If they’re off by even a little bit, they correct themselves. This “closed-loop system” ensures they know where they are at all times, which is perfect when precision really matters.

-

Torque: Servo motors are known for their high torque at high speeds, making them ideal for applications where power and speed are a priority. If your project involves moving heavier loads quickly and accurately (think robots or automated doors), servo motors are your go-to.

-

Smooth Motion: Unlike stepper motors, which might seem like they’re dancing at times, servo motors move fluidly. This makes them perfect for things like camera gimbals, where you need smooth and steady motion.

Use Cases for Servo Motors:

- Robotics: Servo motors are great for things like robotic joints, where you need both power and precision.

- RC Vehicles: In the world of remote-control cars, boats, and planes, servo motors are used to control steering and other precise movements.

- Camera Gimbals: If you’ve ever seen a smooth, cinematic camera pan, there’s probably a servo motor behind it.

Drawbacks? Servo motors tend to be more expensive than stepper motors. They’re also more complex since you need to set up the feedback system, which can be a little trickier for beginners.

Stepper Motor vs. Servo Motor: Which Should You Choose?

Alright, now that we know what each motor does, it’s decision time. Let’s break it down:

-

Precision and Accuracy

-

Winner: Stepper Motor (for most applications)

Stepper motors excel when you need to know exactly how far something has moved without needing feedback. For precise positioning, they’re rock solid.

But if you need real-time correction and absolute accuracy, go with the servo motor.

-

Winner: Stepper Motor (for most applications)

-

Speed and Power

-

Winner: Servo Motor

If your project involves moving heavy things at high speeds (or both), servo motors are your best bet. They provide high torque and won’t lose their position at high speeds like stepper motors sometimes do.

-

Winner: Servo Motor

-

Cost and Simplicity

-

Winner: Stepper Motor

Stepper motors are generally cheaper and easier to set up, making them perfect for hobbyists or projects where budget matters. Plus, you don’t have to worry about setting up any feedback loops.

-

Winner: Stepper Motor

-

Smoothness of Motion

-

Winner: Servo Motor

For applications where smooth, continuous motion is important (like in camera gimbals or automated doors), the servo motor is the clear winner.

-

Winner: Servo Motor

Which One Is Right for Your Project?

Still can’t decide? Here’s a quick rundown of what you should pick based on your project:

-

Go with a Stepper Motor if:

- You need high precision and are okay with slower speeds.

- Your project involves moving to exact positions without requiring feedback.

- You’re working on a 3D printer, CNC machine, or something that involves precise, repeatable motion.

-

Go with a Servo Motor if:

- You need speed and power.

- Your project requires smooth movement and real-time position adjustments.

- You’re working on robotics, RC vehicles, or any application where torque and accuracy are essential.

Final Thoughts: Stepper vs. Servo

In the battle of stepper motor vs. servo motor, there’s no definitive “best” motor. It’s all about what your project needs! If you want precision and budget-friendly control, a stepper motor will be your hero. But if you’re after power, speed, and smoothness, the servo motor is the better choice.

So, whether you're building a 3D printer or the next cool robot to show off to your friends (or future employers), pick the motor that fits your needs. And remember: the best motor for your project is the one that gets you from Point A to Point B without turning your project into a fire hazard.